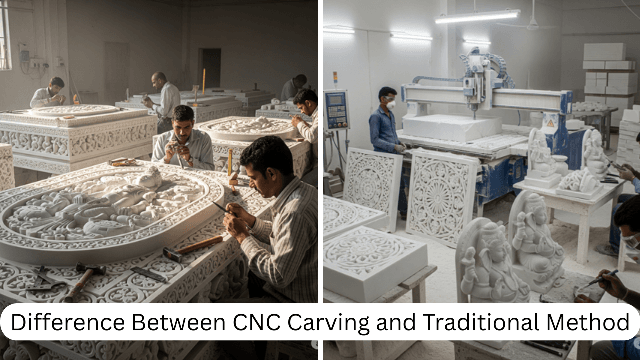

Difference between Modern CNC Carving and Classic Traditional Method

Makrana, located in Rajasthan, India, is renowned worldwide for its high-quality white marble, which has been used in iconic structures like the Taj Mahal and numerous temples. This marble, often over 99% calcite, is prized for its purity, durability, and ability to retain shine, making it ideal for intricate carvings in temple works. Traditional carving in Makrana follows ancient practices rooted in Shilpa Shastra, an age-old Indian tradition of arts and crafts passed down through generations of artisans. CNC (Computer Numerical Control) carving, a more recent innovation, uses computer-guided machines to automate the process. Both methods are employed in Makrana for creating temple elements, such as idols, mandirs (home altars), pillars, and friezes, but they differ significantly in approach, outcomes, and applications.

Below is a comparison of the two methods, based on key aspects: 6 Difference between Modern CNC Carving and Classic Traditional Method

| Aspect | Traditional Carving | CNC Carving |

|---|---|---|

| Process | Hand-carved using tools like chisels, hammers, mallets, rasps, and polishing stones. Artisans manually chip away at the marble, relying on skill, patience, and tactile feedback to shape the stone. | Computer-controlled machines use diamond-tipped tools, routers, and software (e.g., 3D modeling) to cut, engrave, and shape marble based on digital designs. Often involves multi-axis machining for complex forms. |

| Time and Efficiency | Time-intensive; a single sculpture or temple panel can take weeks or months due to manual labor. Suitable for bespoke pieces but not scalable. | Much faster (25-50% quicker than hand carving for similar projects); ideal for producing multiple items efficiently, reducing production time from weeks to days. |

| Precision and Accuracy | High with experienced artisans, but subject to human error, slight imperfections, and variations that add unique character. Limited by tool sharpness and physical strength. | Exceptional precision with minimal errors; machines ensure consistent cuts, symmetrical designs, and intricate details that are hard to achieve manually. Reduces waste and fits pieces seamlessly. |

| Cost | Higher labor costs due to skilled artisans and longer timelines; economical for small, one-off artisanal works but expensive for volume. | Lower overall costs for larger runs due to automation and reduced labor; high initial setup (machines and software) but cost-effective long-term, especially for repeatable designs. |

| Artistic Quality and Uniqueness | Emphasizes authenticity, cultural heritage, and a “handmade soul” with subtle imperfections that convey emotion and tradition. Each piece is truly unique. | Highly reproducible with exact replicas; excels in complex, symmetrical patterns but may feel more mechanical or lack the organic warmth of hand-carved work. Often combined with hand-finishing for added artistry. |

| Physical Demand and Safety | Physically demanding, requiring strength and endurance; higher risk of injury from tools and dust, though it fosters a deep connection with the material. | Less strenuous on artisans; automated processes improve safety with features like dust collection and overload protection, minimizing human exposure to hazards. |

| Scalability and Customization | Limited scalability; best for custom, artistic creations but challenging for mass production or identical replicas. | Highly scalable for producing multiples; allows easy customization via digital edits, enabling exploration of colors, finishes, and materials without restarting from scratch. |

| Environmental Impact | Lower energy use but generates dust; relies on manual methods, which can be more sustainable in small-scale operations. | Higher energy consumption from machines; however, precision reduces material waste, and modern systems often include eco-friendly features like recyclable water in waterjet integrations. |

Highlighting Temple Works for Home and Community in Makrana

In Makrana, marble carving is deeply tied to temple architecture, where the stone’s water-resistant and shine-retaining properties make it perfect for ornate works like deities (e.g., Ganesh, Krishna), inlays, and structural elements. Traditional methods preserve cultural significance, especially in community temples, while CNC enhances efficiency for home use.

- Home Temple Works (e.g., Indoor Mandirs, Small Idols): These are typically smaller (4-6 feet high) and focus on personal worship spaces in residences. Traditional carving shines here for its artisanal touch, creating bespoke pieces with intricate motifs that carry emotional and spiritual value, often costing Rs 75,000–2,50,000 per unit. However, CNC is increasingly popular for home temples due to its speed and affordability, allowing precise, detailed designs like floral patterns or inlays without the high labor costs of handwork. It’s ideal for modern households seeking quick, customizable options, such as combining CNC-cut bases with hand-polished finishes. This hybrid approach reduces time while maintaining elegance, making Makrana marble accessible for everyday devotion.

- Community Temple Works (e.g., Large Sculptures, Pillars, Friezes): These involve grander scales for public or village temples, emphasizing heritage and durability for monuments like the Jain Dilwara Temples. Traditional carving is preferred to honor Shilpa Shastra traditions, ensuring unique, soulful elements that reflect communal identity and craftsmanship passed through generations. Artisans create elaborate sculptures and architectural features that withstand time, though it’s labor-intensive. CNC supports larger projects by handling rough shaping or repetitive elements (e.g., uniform pillars), speeding up construction while artisans add final details manually. This is crucial for community projects with tight timelines or budgets, blending precision with cultural authenticity.

In Makrana, a hybrid model is common: CNC for initial cuts and traditional for refinements, balancing efficiency with artistry. Traditional methods dominate for their cultural depth, while CNC grows for its practicality in meeting modern demands for home and community temples.

The Carver’s Dilemma

An interactive analysis of Makrana’s marble industry, where ancient tradition guided by *Shilpa Shastra* meets the digital precision of CNC technology.

The Process Unveiled: Hand vs. Machine

Traditional Workflow: The Ustaji’s Art

Design Transfer

Designs are manually drawn onto the marble with pencils or chalk.

Rough Carving (‘Gadhai’)

Bulk material is removed with mallets and larger chisels.

Detailed Shaping

Finer tools like small chisels and rasps refine the form.

Finishing & Polishing

The surface is polished by hand to achieve a lustrous finish.

CNC Workflow: Digital Engineering

3D Digital Design (CAD)

A precise 3D model of the final piece is created in software.

Toolpath Programming (CAM)

Software generates G-code instructions for the machine.

Automated Carving

Multi-axis machines with diamond tools execute the code.

Quality Control & Finishing

The piece is inspected and may receive minor hand-finishing.

Head-to-Head: A Data-Driven Comparison

The choice between methods has profound implications for production time, cost structure, and the final product’s characteristics. The data reveals a story of trade-offs between speed and scalability versus initial investment and artistic uniqueness.

Production Time

CNC technology drastically reduces the time from concept to completion. A job of several weeks can be done in days.

Cost Structure Breakdown

Traditional carving has low startup costs but high labor per piece. CNC is the opposite, with high initial investment but lower per-unit costs.

Core Attributes Compared

Each method excels in different areas. CNC offers unmatched precision and scalability, while traditional methods provide unique, one-of-a-kind artistry.

Artistry: Soul vs. Precision

The central debate revolves around the definition of artistry. Is it found in the “human touch”—the subtle imperfections and intuitive decisions of a master artisan—or in the flawless execution of a complex digital design?

The Value of Tradition

❤️

Celebrated for its “soul,” “warmth,” and “emotional depth.” Each piece is unique, carrying the artisan’s signature and a direct connection to cultural heritage.

The Power of CNC

🧠

Enables “unprecedented freedom” and “complex geometries” previously impossible. The artistry lies in the digital design and programming.

Market Focus: Who Buys What?

The two methods cater to distinct market segments. Traditional carving thrives in niches that value cultural authenticity and timeless elegance, while CNC serves modern, commercial demands for consistency and contemporary design.

Traditional Carving Market

Focus on heritage, spiritual, and luxury bespoke projects.

CNC Carving Market

Focus on modern, commercial, and high-volume applications.

The Future is a Hybrid

The path forward for Makrana lies not in choosing one method over the other, but in fostering a symbiotic relationship. By blending the irreplaceable skill of the artisan with the precision of technology, Makrana can preserve its rich heritage while innovating for a global market. Initiatives like the GI tag for Makrana Marble and the Makrana Artisan Welfare Society are vital in supporting this evolution.

We hope, You may like this post highlighting 6 Difference between Modern CNC Carving and Classic Traditional Method